industrial vibratory separator screens

American Society of Mechanical Engineers (ASME)

Society of Petroleum Engineers (SPE)

Bob DeWolfe has extensive field, technical services, and operational

management experience in the energy industry with drilling fluids, solids

management, and refinery waste management.

Fred Growcock

Former Global Fluids Specialist at Oxy

APHRON drilling fluids are highly shear-thinning water base fluids containing stabilized air-filled bubbles and are able to seal loss zones with non-permanent formation damage

coal liquefaction and gasification

gas-cooled nuclear reactors

reservoir stimulation

acid corrosion inhibition

foamed fracturing

API and Drilling Waste Management Group (DWMG)

Society of Petroleum Engineers and is affiliated with American Association of Drilling Engineers (AADE), API and ASME.

Todd H. Lee is the marketing manager for National Oilwell, with

13 years’ experience sizing, training, and troubleshooting centrifugal

pumps.

wellhead and valves, pressure control, subsea controls,

drilling instrumentation, and solids control.

mechanical engineering design, and sales and marketing.

chemical engineering, petroleum engineering, and international finance.

petroleum, mining, and utilities business sectors

wire cloth and shaker screens

Encyclopedia of Environmental Analysis and Remediation

underbalanced drilling

the International Association of Drilling Contractors

IADC Mud Equipment Manual

IADC Rig Instrumentation and Measurements Committee (RIM). RIM

IADC Shale Shaker Handbook

American Association of Drilling Engineers (AADE)

AADE Shale Shaker Handbook

sand traps

erroneous: wrong

fallacious: based on a mistaken belief.

detrimental: tending to cause harm.

foster the havoc: to cause great damage.

The secret to drilling safely, fast, and under budget is to remove

drilled solids. Drilled solids increase drilling costs, damage reservoirs,

and create large disposal costs. Specific problems associated with drilled

solids are:

. Filtrate damage to formations

. Drilling rate limits

. Hole problems

. Stuck pipe problems

. Lost circulation problems

. Direct drilling-fluid costs

. Increased disposal costs

eradication: the complete destruction of something.

subtle: (of a mixture or effect) delicately complex and understated.

The effects of drilled solids on the economics of drilling a well are

subtle. Increasing drilled-solids content does not immediately result in

disaster on a drilling rig. When a drill bit ceases to drill and torque

increases, a driller knows immediately that it is time to pull the bit.

When drilled solids increase, the detrimental effects are not immediately

apparent.

drill bit

drill bit cutter

disintegration: the breaking down of something into small particles or into its constituent elements.

plumbing: the system of pipes, tanks, fittings, and other apparatus required for the water supply, heating, and sanitation in a building.

manifold of plumbing

slough: remove; get rid of (something undesirable or no longer required).

circulate: move or cause to move continuously or freely through a closed system or area.

Solids-control equipment, also called solids-removal equipment or

drilled-solids management equipment.

This equipment includes gumbo removers, scalper shakers, shale shakers, dryer shakers, desanders, desilters, mud cleaners, and centrifuges. These components, in various arrangements, are used to remove specific-size particles from drilling fluid. Knowledge of operating principles of auxiliary equipment, such as agitators, mud guns, mud hoppers, gas busters, degassers, and centrifugal pumps, is necessary to properly process drilling fluid in surface systems.

heretofore: before now.

polymers

Polymer drilling fluids require lower drilled-solids concentration, so superior solidsremoval systems were developed to meet those demands.

percussion: the striking of one solid object with or against another with some degree of force.

suspend: hang (something) from somewhere.

(For a discussion of cable tool drilling, see History of Oil Well

Drilling by J. E. Brantley.)

bail: leave, back out of.

Solids (clay) in the drilling fluid were considered necessary to support the walls of the borehole.

advent: the arrival of a notable person, thing, or event.

The term disaggregation was used to describe what happened to the

drilled clays. Clays would cause the circulating fluid to thicken, thus

increasing the viscosity of the fluid. Some of the formation drilled would

not disperse but remain as rock particles of various sizes commonly

called cuttings.

disperse: distribute or spread over a wide area.

discretion: caution.

gravity settling

be entrained with: to draw along with or after oneself.

modification: a change made.

Shale is a fine-grained, sedimentary rock formed as a result of the compaction of clay, silt, mud and organic matter over time and is usually considered equivalent to mudstone.

detrimental: tending to cause harm.

cone classifier

The basic principle of the separation of heavier (and coarser) materials from the drilling fluid lies in the centrifugal action of rotating the volume of solids-laden drilling fluid to the outer limit or periphery of the cone.

Application of this centripetal acceleration causes heavier particles to

move outward against the walls of the cone. These heavier particles exit

the bottom of the cone and the cleaner drilling fluid exits from the top of

the cone.

penetration: the action or process of making a way through or into something.

George Stonewall Ormsby

These hydrocyclones were usually loaded with solids because of the

coarse screens on the shale shakers. Removing more of the intermediate

size particles led to the development of the circular motion shale shakers.

Development was slow for these so-called fine

screen–high speed shakers for two reasons: First, screen technology was

not sufficiently developed for screen strength, so screen life was short.

There was not sufficient mass in the screen wires to properly secure the

screens without their tearing. Second, the screen basket required greater

development expertise than had been required for earlier modifications

in drilling-fluid handling equipment.

oblong: rectangular

In the 1970s the mud cleaner was developed. During this period,

no shale shaker could handle the full rig flow on an API 200 screen.

Desanders and desilters were normally used after the shale shaker;

however, they discarded large quantities of barite when used on a

weighted drilling fluid—this meant drilled solids larger than an API 80

and the upper limit of the barite size. API specifications currently allow

three weight percent of barite larger than 74 microns, which is an API

200 screen. To solve this problem, the underflow from desanders and

desilters was presented to a pretensioned API 200 screen on a shaker.

superfluous: unnecessary, especially through being more than enough.

The dryer has a closed sump under the screen with a pump installed. Any liquid in the sump is returned to the active system through centrifuge

sump: a pit or hollow in which liquid collects, especially one in the floor of a mine or basement.

dump truck

gumbo conveyer

pliable: easily bent; flexible.

Neophytes in drilling have a tendency to try to minimize the cost of each category of expense on the basis of the misconception that this will minimize the cost of the well.

Minimizing individual items will only minimize the total if there is no dependence of variables on other costs. For example, increasing mud weight with drilled solids is cheaper than using barite. The cost savings from not purchasing barite is easy to calculate. The cost of all of the problems that ensue is much more difficult to predict. This is the insidious nature of drilled solids.

Decreasing individual costs to decrease the total cost is somewhat analogous to the accountant with appendicitis who decides to save money by renting a room at a cheap motel and calling a doctor friend rather than going to a hospital for an appendectomy.

Room and board

might be cheaper, but the net cost of improper care will probably

make the decision very costly. Extra costs can be incurred because of

inadvisable decisions to cut costs in easily monitored expenses while

drilling wells. When line items are independent of each other, minimization of each line item will result in the lowest possible cost. When

line items are interconnected, minimization of each line item may be

very expensive. Drilled-solids concentrations and trouble costs (or costs

of unscheduled events) are very closely intertwined.

circulate: move or cause to move continuously or freely through a closed system or area.

reservoir: a large natural or artificial lake used as a source of water supply.

inhibit: hinder, restrain, or prevent (an action or process).

Drilling fluids satisfy many needs in their capacity to do the following

[M-I llc]:

. Suspend cuttings (drilled solids), remove them from the bottom of the

hole and the well bore, and release them at the surface

. Control formation pressure and maintain well-bore stability

. Seal permeable formations

. Cool, lubricate, and support the drilling assembly

. Transmit hydraulic energy to tools and bit

. Minimize reservoir damage

. Permit adequate formation evaluation

. Control corrosion

. Facilitate cementing and completion

. Minimize impact on the environment

. Inhibit gas hydrate formation

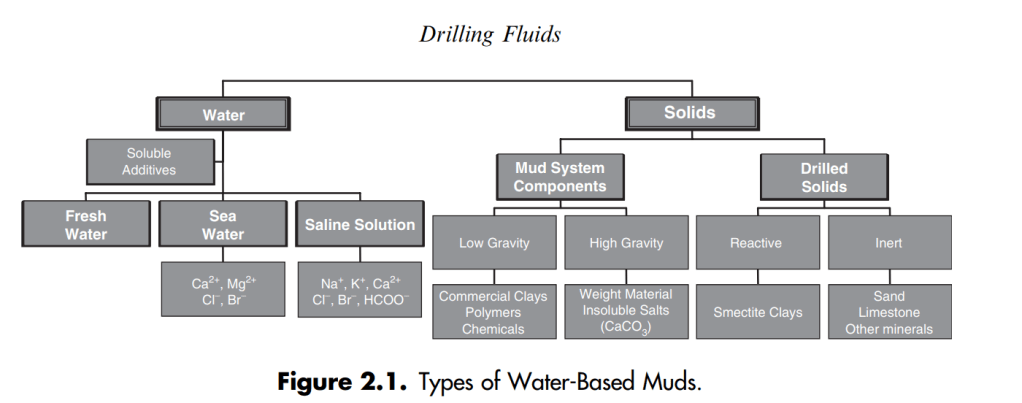

Drilling fluids are classified according to the type of base fluid and other

primary ingredients:

. Gaseous: Air, nitrogen

. Aqueous: Gasified—foam, energized (including aphrons)

Clay, polymer, emulsion

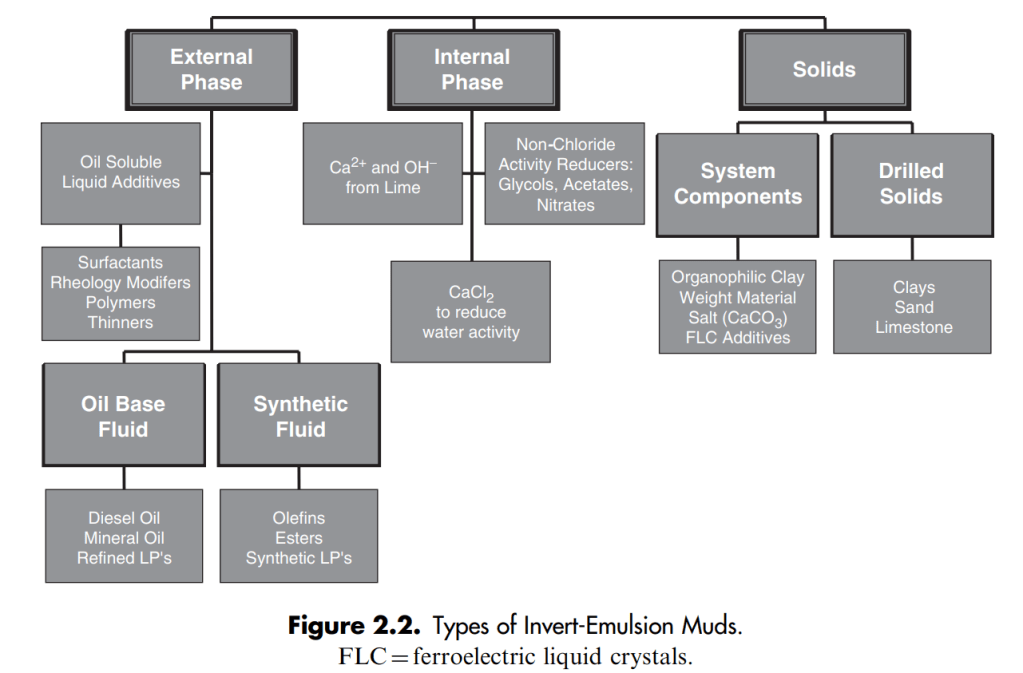

. Nonaqueous: Oil or synthetic—all oil, invert emulsion

True foams contain at least 70% gas (usually N2, CO2, or air) at the

surface of the hole, while energized fluids, including aphrons, contain

lesser amounts of gas. Aphrons are specially stabilized bubbles that

function as a bridging or lost circulation material (LCM) to reduce mud

losses to permeable and microfractured formations. Aqueous drilling

fluids are generally dubbed water-based muds (WBMs), while nonaqueous drilling fluids (NAFs) are often referred to as oil-based muds

(OBMs) or synthetic-based muds (SBMs). OBMs are based on NAFs

that are distilled from crude oil; they include diesel, mineral oils, and

refined linear paraffins (LPs). SBMs, which are also known as pseudo–

oil-based muds, are based on chemical reaction products of common

feedstock materials like ethylene; they include olefins, esters, and

synthetic LPs.

Drilling-fluid costs can constitute a significant fraction of the overall costs of drilling a well.

waste disposal

incur: become subject to (something unwelcome or unpleasant) as a result of one’s own behavior or actions.

Until recently, waste WBMs did not require any treatment and could

be discharged directly into the environment. However, a number of

components in WBMs are becoming increasingly restricted or prohibited. Chrome-containing materials, such as chrome lignosulfonates, are

prohibited in many areas by governmental regulations. Tight restrictions

are imposed in many areas on chloride, nitrate, and potassium salts, or,

more generally, on the total electrical conductivity of the mud. In the

North Sea, use of polyacrylamide polymers, such as partially hydrolyzed

polyacrylamide (PHPA), is also severely restricted. OBMs tend to be

restricted even more than WBMs, especially offshore, and in many places

they can be used only if a zero discharge strategy (sometimes called

a closed loop system) is adopted [Lal & Thurber].

zero discharge strategy = closed loop system

The types and quantities of solids (insoluble components) present in

drilling mud systems play major roles in the fluid’s density, viscosity,

filter-cake quality/filtration control, and other chemical and mechanical

properties. The type of solid and its concentration influences mud and

well costs, including factors such as drilling rate, hydraulics, dilution

rate, torque and drag, surge and swab pressures, differential sticking, lost

circulation, hole stability, and balling of the bit and the bottom-hole

assembly. These, in turn, influence the service life of bits, pumps, and

other mechanical equipment. Insoluble polymers, clays, and weighting

materials are added to drilling mud to achieve various desirable

properties.

surge and swab pressures

The yield point is defined as the point at which the material starts to deform plastically.

tolerate: allow the existence, occurrence, or practice of (something that one dislikes or disagrees with) without interference.

dispersion: the state of getting dispersed or spread.

suspension: strop

Lignosulfonates (LS) are water-soluble anionic polyelectrolyte polymers: they are byproducts from the production of wood pulp using sulfite pulping.

bbl: barrel

Solids removal on the rig is accomplished by one or more of the

following techniques:

. Screening: Shale shakers, gumbo removal devices

. Hydrocycloning: Desanders, desilters

. Centrifugation: Scalping and decanting centrifuges

. Gravitational settling: Sumps, dewatering units

apparatus: the technical equipment or machinery needed for a particular activity or purpose.

Nonaqueous Fluids (NAF) cutting dryer, rotating shaker.

A vacuum or atmospheric degasser is sometimes installed (before any centrifugal

pumps, typically between the shakers and desanders) to remove

entrained air that can cause pump cavitation and reduction in mud

density.

Cavitation occurs when the liquid in a pump turns to a vapor at low pressure. It occurs because there is not enough pressure at the suction end of the pump, or insufficient Net Positive Suction Head available (NPSHa).

impetus: the force or energy with which a body moves.

With the advent of closed loop systems, dewatering of WBMs

has received strong impetus, and it has been found useful to add a

dewatering unit downstream of a conventional solids-control system

[Amoco]. Dewatering units usually employ a flocculation tank—with

a polymer to flocculate all solids—and settling tanks to generate solidsfree liquid that is returned to the active system. Dewatering units reduce

waste volume and disposal costs substantially and are most economical

when used to process large volumes of expensive drilling fluid.

intrinsic: belonging naturally; essential.

Cuttings hydrate

Salinity is the dissolved salt content of a body of water.

deviate: depart from an established course.

comminution: the action of reducing a material, an ore, to minute particles or fragments.

Accordingly, the particle size distribution (PSD)

seen at the flowline can range from near-original cutting size to

submicron-sized particles.

A separate scalping shaker may

be installed ahead of the regular battery of shakers to remove the LCM

and recycle it back into the mud system.

A particle size distribution indicates the percentage of particles of a certain size (or in a certain size interval). These intervals are also called size classes or fractions. A simple example is shown below. Here, a mixture of grinding balls has been separated by size: 5 mm, 10 mm, 15 mm and 40 mm: 5 mm.

Granulometry is the measurement of the size distribution in a collection of grains.

Diffraction is the spreading out of waves as they pass through an aperture or around objects.

Aperture refers to the opening of a lens’s diaphragm through which light passes.

displace: move (something) from its proper or usual position.

Resistance is a measure of voltage divided by resistance in a resistor. Impedance is the generalized notion of voltage divided by current for any component.

disperse: distribute or spread over a wide area.

Viscosity is a measure of a fluid’s resistance to flow.

Xanthan gum is a polysaccharide with many industrial uses, including as a common food additive.

A histogram is a chart that plots the distribution of a numeric variable’s values as a series of bars.

Calibration is the process of configuring an instrument to provide a result for a sample within an acceptable range.

Oscillation is defined as the process of repeating variations of any quantity or measure about its equilibrium value in time.

effluent: liquid waste or sewage discharged into a river or the sea.

Fracture gradient (FG), also known as frac gradient, is the pressure gradient at which the formation breaks.

Rheology is the science of measurement of deformation.

inasmuch: to the extent that; insofar as.

comminuted: reduced to minute particles or fragments.

Surface-area increase due to

comminution is proportional to the decrease in particle diameter. For

example, breaking up a 100-mm-diameter particle into 5-mm particles will

increase the total surface area by a factor of 20. Consequently, the

amount of mud adsorbed on the solids, in this case, will increase roughly

by a factor of 20 as a direct result of comminution. Low-shear-rate

viscosity will also increase significantly with this increase in total surface

area, though the relationship is not strictly linear.

intrinsic: belonging naturally; essential.

Le Chatelier Specific Gravity Flask is useful for specific gravity determinations of hydraulic cement, sand, and other fine materials. The body holds about 250ml and the bulb in the neck holds 17ml. Graduations are located 0-1ml below the bulb as well as 18-24ml above the bulb.

hematite, also spelled haematite, heavy and relatively hard oxide mineral, ferric oxide (Fe2O3), that constitutes the most important iron ore because of its high iron content (70 percent) and its abundance.

incremental: relating to or denoting an increase or addition, especially one of a series on a fixed scale.

Kerosene oil is a flammable liquid which is used in many industries and homes around the world as a fuel for light, heat and power.

Gas pycnometer measures the skeletal volume of a material by gas displacement using the volume-pressure relationship of Boyle’s Law. The Stereopycnometer is the standard model of the series of manually operated pycnometers.

granule, flake, fiber

Asphaltenes are molecular substances that are found in crude oil, along with resins, aromatic hydrocarbons, and saturates (i.e. saturated hydrocarbons such as alkanes).

viscoelasticity is the property of materials that exhibit both viscous and elastic characteristics when undergoing deformation.

A retort is a reactor that has the ability to pyrolyze pile-wood, or wood logs over 30 centimetres (12 in) long and up to 18 centimetres (7.1 in) in diameter.

adsorb: (of a solid) hold (molecules of a gas or liquid or solute) as a thin film on the outside surface or on internal surfaces within the material.

gunk up: (informal) to make something dirty with a sticky substance.

initiation: the action of beginning something.

solvent: having assets in excess of liabilities; able to pay one’s debts.

substrate: an underlying substance or layer.

alleviate: make (suffering, deficiency, or a problem) less severe.

Gas pycnometer:

stereopycnometer:

retort:

inert: lacking the ability or strength to move.

inert: lacking the ability or strength to move.

Since all particles are enveloped by drilling fluid,

attractive forces among strongly interacting particles (e.g., clays, drilled

solids) generally lead to higher internal friction, hence a higher viscosity.

Repulsive force: the force by which bodies repel one another.

Gumbo soil is a mixture which often has some small amounts of sand and/or organic material, but is typically defined by the overwhelming presence of very fine particles of clay.

intricate: very complicated or detailed.

To optimize a drilling operation, it is important to understand

how the solids affect bulk mud properties, particularly rheology, hole

cleaning, filtration, drilling rate.

Shear is the change of shape, without change of volume, of a layer of the substance, produced by a pair of equal forces acting in opposite directions along the two faces of the layer.

Drilling fluids with elevated viscosity at high shear rates

tend to exhibit greater retention of mud on cuttings and reduce the

efficiency of high-shear devices like shale shakers [Lundie]. Conversely,

elevated viscosity at low shear rates reduces the efficiency of low-shear

devices like centrifuges, inasmuch as particle settling velocity and

separation efficiency are inversely proportional to viscosity.

extensional viscoelasticity.

An orifice is an opening or a hole.

shale encapsulation: In drilling fluid parlance, the absorption of a polymer film onto cuttings and wellbore walls to form a coat or barrier.

stipulate: demand or specify (a requirement), typically as part of an agreement.

annulus: a ring-shaped object, structure, or region.

Fann Reading

Good cuttings transport is indicated by sharp edges on the

cuttings, whereas smooth and/or small cuttings can indicate poor hole

cleaning and/or poor inhibition. With the advent of PWD (pressure

while drilling) tools and accurate flow modeling, a number of other

indicators have come to light that foreshadow poor hole cleaning and its

attendant consequences. Among these are:

. Fluctuating torque

. Tight hole

. Increasing drag on connections

. Increased ECD when initiating drill string rotation

agglomerated: collect or form into a mass or group.

deviate: depart from an established course.

penetration: the action or process of making a way through or into something.

turbulent: (of air or water) moving unsteadily or violently. turbulent flow.

Hydrostatic pressure arises due to the weight of a fluid acting on an object.

interstice: gap, space, an intervening space, especially a very small one.

Permeability: the state or quality of a material or membrane that causes it to allow liquids or gases to pass through it.

granular: resembling or consisting of small grains or particles.

Surfactants are chemical compounds that decrease the surface tension or interfacial tension between two liquids, a liquid and a gas, or a liquid and a solid.

emulsifier: food additives used to help mix two substances that typically separate when they are combined.

ammonia: found throughout the environment in the air, soil, and water, and in plants and animals, including humans.

volatile amies: characteristic molecules responsible for the fishy odour and flavour present in fish several days after the catch and they are commonly used as criteria for assessing the fish quality.

combustible: able to catch fire and burn easily.

requisite: made necessary by particular circumstances or regulations.

unconsolidated: consisting of particles that do not stick together.

deplete: use up the supply or resources of.

infused: fill; soak (tea, herbs, etc.) in liquid to extract the flavor or healing properties.

convolute: (especially of an argument, story, or sentence) extremely complex and difficult to follow.

surfactant: a substance which tends to reduce the surface tension of a liquid in which it is dissolved.

bridging material

inhibitive: to restrain.

imbibe: absorb in water

flocculate: form or cause to form into small clumps or masses.

disperse: distribute or spread over a wide area.

ventilation: the provision of fresh air to a room, building, etc.

brine: water saturated or strongly impregnated with common salt.

A solvent is a substance that dissolves a solute, resulting in a solution. A solvent is usually a liquid but can also be a solid, a gas, or a supercritical fluid.

Reagents are commonly used to test for the presence of certain substances, as the binding of reagents to the substance or other related substances triggers certain reactions.

incompatible:(of two things) so different in nature as to be incapable of coexisting.

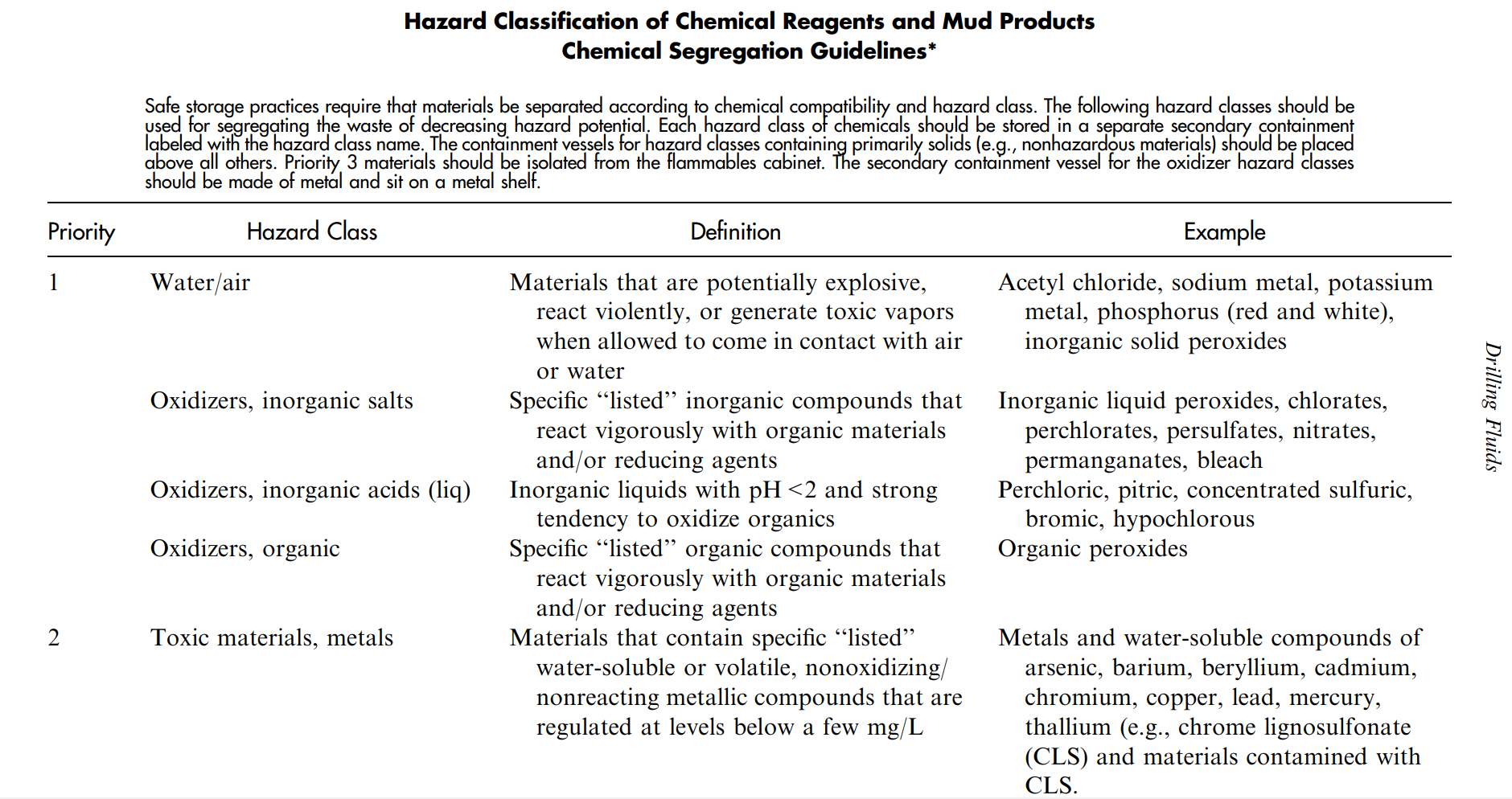

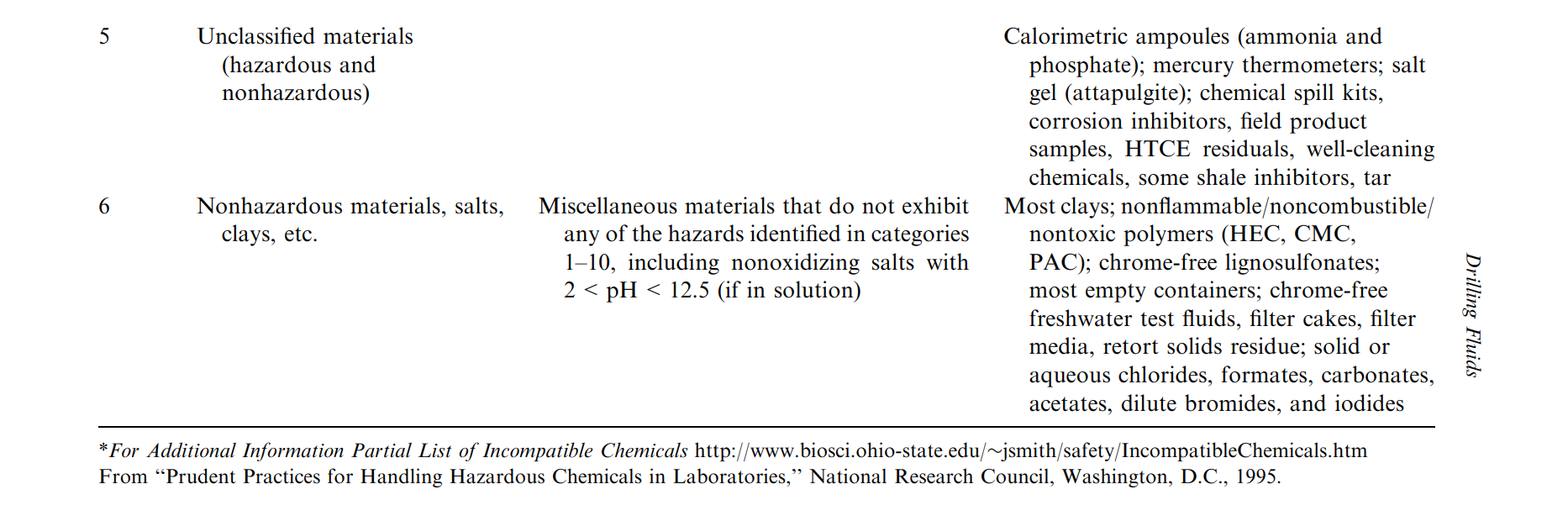

Mud products and test reagents are classified into six hazard groups, in

decreasing order of hazard risk (priority)—reactive/oxidizer, toxic,

flammable, acids and bases, unknown, and nonhazardous—and each

group should be segregated from the others. There should be very little

or no material on the rig that falls into the reactive/oxidizer category.

Acids and bases, though grouped together, should be placed in separate

spill trays.

Triethanolamine is a tertiary amino compound that is ammonia in which each of the hydrogens is substituted by a 2-hydroxyethyl group.

thixotropy: the property of becoming less viscous when subjected to an applied stress, shown for example by some gels which become temporarily fluid when shaken or stirred.

An oxidizing agent is a substance in a redox chemical reaction that gains or “accepts”/”receives” an electron from a reducing agent.

vigorously: in a way that involves physical strength, effort, or energy; strenuously.

In chemistry, volatility is a material quality which describes how readily a substance vaporizes.

Cyanide is a rapidly acting, potentially deadly chemical that interferes with the body’s ability to use oxygen.

Disulfides play a crucial role in maintaining the structure of many proteins including insulin, keratin, and many other structurally important proteins.

combustible: able to catch fire and burn easily.

A nonhalogenated compound is one which does not have a halogen (e.g., fluorine, chlorine, bromine, or iodine) attached to it.

flashpoint: the lowest temperature at which vapors above a volatile combustible substance ignite in air when exposed to flame.

decomposition: the state or process of rotting; decay.

Buffer Solution is a water solvent based solution which consists of a mixture containing a weak acid and the conjugate base of the weak acid, or a weak base and the conjugate acid of the weak base. They resist a change in pH upon dilution or upon the addition of small amounts of acid/alkali to them.

retort: heat in a retort in order to separate or purify.

Attapulgite is a magnesium aluminium phyllosilicate which occurs in a type of clay soil common to the Southeastern United States.

titration, process of chemical analysis in which the quantity of some constituent of a sample is determined by adding to the measured sample an exactly known quantity of another substance with which the desired constituent reacts in a definite, known proportion.

inert: lacking the ability or strength to move.

crucible: a ceramic or metal container in which metals or other substances may be melted or subjected to very high temperatures.

Leave a comment