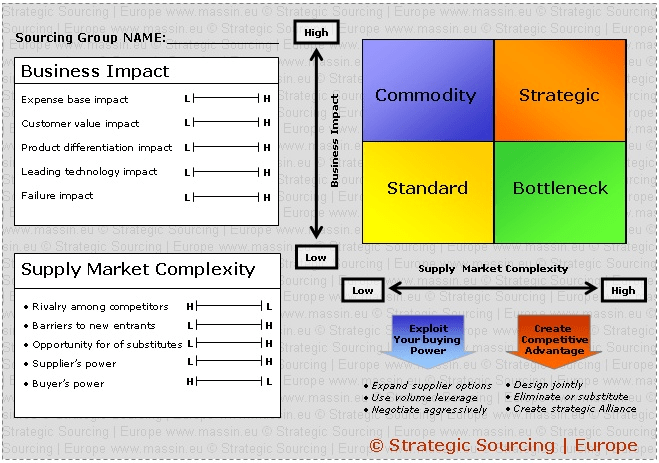

Once internal company requirements and external market conditions have been brought together, the Purchasing department will review the strategic importance of the individual commodity groups. To do so, the portfolio technique as shown below, by which the requirements of the criteria “company relevance” and “market relevance” are divided into the following four commodity groups:

Non-critical Commodity Groups

Commodity groups classified as “non-critical” are characterized by low volumes, high availability, and low complexity. Typically, these groups encompass “C” items (identified with the help of an ABC analysis) such as screws, standard parts, and indirect materials such as ancillary and operating materials or office supplies. With respect to non-critical commodity groups, the target must be to buy them at the best price while reducing supervision to a minimum. At the extreme, this may be achieved by outsourcing to a purchasing service provider or by automated order processes within the scope of an e-procurement system.

Bottleneck Commodity Groups

While “bottleneck commodity groups” may also be characterized by low volumes, purchasing them is complicated by low availability and/or high complexity. As a rule, the procurement volumes are too low to either arouse the suppliers’ interest or initiate internal measures by which the respective item might be simplified or replaced. In many cases, the only possible solution will be risk minimization by providing high-safety stocks.

Leverage Commodity Groups

“Leverage” products are the Buyer’s “bread-and-butter” business. They are characterized by high volumes, high availability, and low complexity. Thanks to high purchasing volumes and strong supplier competition, cost reductions can be achieved easily.

Strategic Commodity Groups

These products are characterized by high volumes, low availability, high procurement risks, and high complexity. These commodities must be managed most thoroughly, e.g. by the development of strategic suppliers, by comprehensive risk management, and by incessant procurement market

research.

By classifying the demands, basic strategies can be developed that allow for the management of supply, costs, and also the risks of the individual commodity groups. On this basis, the Purchasing department has to develop the best possible procurement strategy with respect to particular materials in order to satisfy all relevant demands in an optimal manner.

Strategist is now called upon as a Commodity Group Manager who should be intensively involved in the “actual” and “target” positions and independently develops the strategic roadmap. In doing so, he transforms the Procurement Program Policy, the contract, and the supplier policies, which resulted from the overall business strategy, into a plan. A positive side effect is that the leap of faith invested in the Strategist responsible (a method I often used with young members of staff) will greatly boost his or her motivation—the future development of the respective commodity group will thus become his or her special concern. The individual plans are presented by the responsible Strategists in biannual strategy workshops. These plans are then optimised by the whole team, and regular progress reports are then prepared.

Leave a comment